Projects

SUMMERISATION OF NALUT - CEMENT FACTORY – PROJECT

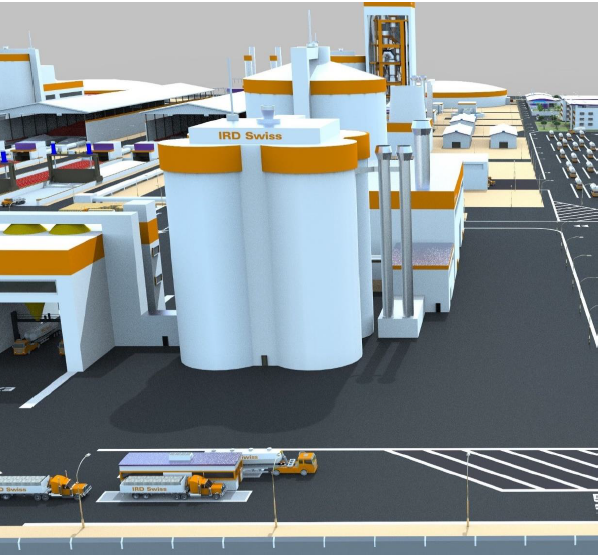

From importing building materials, the company stopped from 2011 to 2019 but is now back and presenting its first project: an eco-friendly cement factory using modern German technology to produce up to 14,000 tons per day.

The Company, ALHEDAB Cement Company, aims to establish and

operate a new cement plant for the production of all types of PORTLAND™ cement,

complementary and subsequent industries. Commercial register no. 909 has been

issued on 16/MAY/2012.

On 24/OCT/2019, an agreement was made with the National

Mining Corporation for utilising the following quarries for thirty years from

the beginning of actual production in return for paying 3% of net profit/to

final product (cement/clinker) at plant site; this would mean that a max. of

0.05 €/to of raw materials.

•

Clay quarry at Wazin City,

Gypsum quarry at Bir Al-Ghanam.

•

Limestone quarry Nalut in

front of the plant site.

•

Sand quarry Nalut beside to

the Limestone quarry in valley.

An initial approval from the Government of

National Accord Ministry of Local Government

Municipality of Nalut on 24/Mar/2019 was given for establishing an

ordinary Portland cement plant with an annual capacity of 3.6 million

tons.

Therefore, the licenses given must be adapted by ALHEDAB so

as the plant can meet the planned capacity of 12,000 tons per day. This

agreement for increased capacity has already been declared by the Government.

Further negotiations will follow in the next couple of months between the

shareholders of ALHEDAB and the Municipality of Nalut.

It can be assumed that there will be two separate licences

released by the Government, to ensure the ALHEDAB cement factory can produce a

daily capacity of 12,000 TPD PORTLAND™ cement production. It is believed that

the shareholders of ALHEDAB Cement Co. will reach such an agreement before the

finalisation of the plant so that there is no delay to start construction in

January 2024 with the full and complete approvals.

A further objective is to reach an agreement with foreign

purchasers (so called OFF TAKE agreement) that allows ALHEDAB Cement to export

Ordinary Portland Cement™ (OPC) to adjoining countries like Iraq, Syria, Sudan

and Saudi Arabia amongst others, because all those countries have the same

strong need for cement as Libya does.

The finished plant shall be situated in the Municipality of

Nalut, 65 KM road distance eastwards from the Tunisian border. The plant shall

be erected in an area where in a circle of an estimated 350 KM no other Cement

plant exists.

Except for the Clay all the main process additive material

is all in a circle of 6 KM from the plant.

Utility water, for cooling the burning process during the

cement manufacturing, is being supplied from resources that run parallel and

close to the plant site. Having a cheap available source to gain utility water

for a cement plant is not normal in the desert regions and this is a strong

advantage for this project.

The road network ensures a well-connected movement and

transportation route in all directions to the Mediterranean shoreline. The

closest usable Libyan port to ship the cement as well as to unload spares and

low-weight equipment is about 200 KM away at ZUWARA.

There is also the available, more secure and cost effective

option of using the Tunisian Zarzis port ,

a large space storage was offered

to ALHEDAB company by the authority of the port so ships do not have to wait

longer (as is the case in main Libyan ports) therefore a efficient loading

schedule can be achieved.

The new Cement plant will be the largest and most modern

cement plant in the Northern Africa region.

Another significant advantage of this project is the

availability of extremely cheap fuels of HFO and Natural Gas. At the same time,

the project design of this plant will ensure the use of the most modern plant

technology along with state-of-the-art equipment so as to ensure maximum

efficiency and significant cost effective advantages.

The Pros:

ü Excellent raw material qualities in huge quantities available

around the Nalut area.

ü Apart from Gypsum and a small portion (1%) of Iron Ore that will

be delivered from the Gypsum quarry at Bir Al-Ghanam, all raw materials such as

Limestone, Clay, Sand and Marly Limestone are available on or extremely close

to the planned site.

ü The availability of water and natural gas is alongside the

planned construction site of the factory

ü The most expensive cost factor of the Cement factory is the fuel

for firing the kilns and the electric turbine generators. The fuel shall be

natural Gas which is available locally at very cheap costs. This means that

higher margins can be achieved through lower production costs of the

Portland-Cement.

ü Adequate water supplies are available through using the pipeline

of the “Great Man Made River” which runs alongside the planned construction

site therefore there is no expensive deep drilling for water required.

ü The entire Plant is designed for maximum production of

Portland-Cement using highly effective technology from Germany. All equipment

is planned to be delivered from Germany and represents state of the art

equipment in the Cement industry. It has been agreed that the factory will be

supported for the first 10 tears with regards to operating and maintenance

(O&E) therefore there will be adequate technical support so as to maximise

production.

ü It is planned to build a Combined Cycle Power Plant (CCPP) in

conjunction with the construction of the Cement factory so the factory has its

own electricity generation capability making the factory independent of the

grid thereby ensuring continuity. Any surplus power can be delivered (sold via

the grid) to Nalut city as well as to planned new homes surrounding the factory

area.

ü During the erection of the plant all the staff required to run

the plant will be trained as part of the project mobilisation in the projects

own training facility onsite. Only the process control engineers, electric

engineers and laboratory staff will be trained abroad.

ü Producing the highest quality controlled and certified PORTLAND®

Cement means getting the best sale price. Currently Cement prices are rising

steadily. During the feasibility study process which was completed in 2019 it

was calculated a return of 65 EUR/ton, we currently can assume 95 to 110

EUR/ton meaning a potential additional income of more than 30% against previous

projections.

ü It is envisaged that Because of a lack of cement production in

North Africa and the enormous demand of Portland Cement worldwide the Nalut

Cement plant project production will not suffer from lack of demand.

ü Many local wholesalers have already contacted ALHEDAB company to

sign contracts to buy the entire cement production before even starting the

construction of the plant

ü We are confident that the breakeven point of the total CAPEX

investments can be achieved in the 5th year. This means that investors can

achieve a net profit earlier than calculated in the feasibility study.

The Cons:

v The distance between the Nalut project plant and the nearest

available Libyan port in Zwara city is about 200 km and a distance of about 250

km to Tunisia Zarzis port. Therefore, a truck fleet must be purchased to

guarantee a permanent and steady Cement delivery 24 hours. This will increase

the manufacturing cost about 4,50 EUR/Ton.

v The normally cheap available natural Gypsum is about 170 KM far

from the site of the plant. So, the price for getting the Gypsum delivered to

site was also calculated. Because only 5% per ton Cement is required. The cost

of Cement will not exceed 4 EUR / Ton

v The Libyan Dinar is currently not a freely convertible currency.

This means that a higher exchange rate ratio must be calculated as a financial

risk and fiscal agreement with the CBL should be considered. Having said that

entities such as Libyan Iron and Steel Company sell in USD and are therefore

able to mitigate this risk

Final recommendation:

IRD Swiss recommend to potential investors to invest in this

project.